Simple Tech: Electric Motors

The electric motor (EM) is the simplest and most efficient of all the machines in the world. It's hard to imagine why it would take them so long to be considered for mainstream automotive propulsion. Early EM-based automotive prototypes lost to the internal combustion engines (ICEs), which are a lot more complicated. There is the complexity of the construction of an ICE, all of those moving parts... In comparison, the EM has just one moving part, the shaft. And yet, ICEs power most cars and EMs are used basically to turn the ICEs on! Oh and to wipe the windshields also.

Perhaps the biggest reason for this is fuel. It is easy to fill up an ICE and ensure a steady supply of fuel. You drive your car for 5-8 hours and when it starts to run out of petrol or diesel, you pull into a pump where you 'recharge' your fuel supply in 5 minutes and get going. With an electric car, your recharge stop would be 8-10 hours by present standards. And while you might drive 400km on a tankful, the electric will run out in 100-150km.

But the EMs are coming and they're steadily overcoming obstacles. The inroads they are and will make into the industry will be based on their innate simplicity and efficiency, and the steady improvement of battery technology. There's help coming from environmental concerns, industrial push, electric vehicle racing and other areas too. We have discussed batteries before, so let us focus on the engines that will drive our kids, the electric motor.

EMs come in various forms and types but in the auto industry we primarily use the AC induction or DC brushless motor. AC, or alternating current, and DC, or direct current, are two types of electric currents, and it's AC that we get out of the wall sockets in our houses. DC is usually the preserve of batteries and the output terminals of mobile and laptop charging adaptors. The name AC comes from the fact that the current changes direction, usually 50 times a second while DC sticks to one direction. Since electricity conductors create magnetic fields, the DC conductors generate steady fields while AC ones produce a field whose polarity changes 50 times a second. So the choice of AC or DC for a motor is determined by the nature of the work we need the motor to do. And they're not interchangeable.

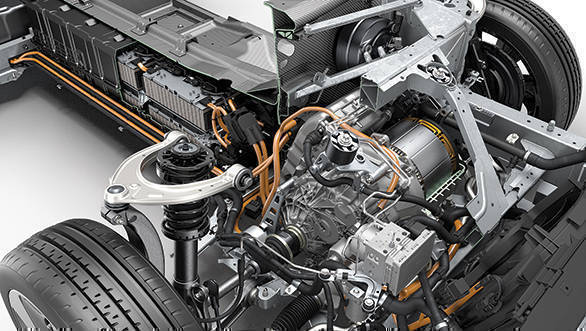

Despite having different applications, EMs are mechanically pretty similar to each other. There is the outer casing, which can be cast iron, steel or aluminium depending on the application of the motor. The casing is usually cylindrical and has a huge maze of distributed wiring arranged and fixed inside it. The free ends of these wiring loops, called the windings, are directed outside the casing to a small terminal box through which it connects to the electricity source. A metal cylindrical shaft - our sole moving part - is placed inside the casing supported on the end covers with ball bearings. Depending on the motor, the shaft can be made of iron, or a permanent or electromagnet. The shaft is free to rotate and has no direct contact with the winding or the casing.

One side of the shaft can have a cooling mechanism if needed while the other connects to the load - a drive shaft, gearbox or wheels, depending on the design of the vehicle. And that, literally, is that. The solitary moving part and simple construction make EMs extremely reliable, and their efficiency is very, very high.

Things get complicated when you start looking at how electricity is used to rotate the shaft. And that's our topic for next month.