Simple tech: Tyre basics

Last month, we focused on the importance of the wheel. The logical progression is therefore the tyre. Tyres are the only component of the car or motorcycle that are in contact with the ground. Without them all the horsepower, torque, gear ratios etc do not matter - because they cannot be transferred to the ground to create movement.

In all modern tyres, the load of the vehicle is carried by the air trapped within them. This is a good method because air is relatively light and because gases get compressed and air pressure can be used to gain some of the advantages that suspension brings to vehicles. That is why when you drive with the correct air pressure, the vehicle feels a lot better to drive.

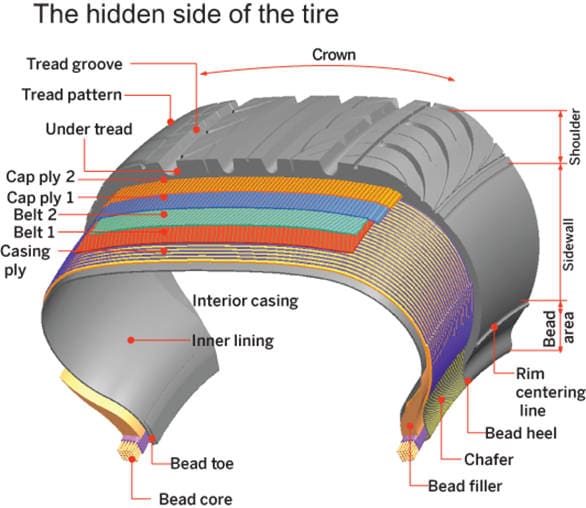

Let us look at a tyre's components and construction. A tyre is made of natural and synthetic rubber, fibre or wire and chemicals to enhance properties of the rubber. The part that is most visible is the tread.

As the outermost part of the tyre (from its geometric centre), it is also the part that is directly in contact with the road. It is pretty thick and made of relatively hard-wearing rubber. The time it takes for the thickness of the rubber to wear out depends on the role of the tyre (in terms of whether it is a sporty tyre or an endurance-oriented tyre).

The tread itself also refers to the pattern in which this rubber is engineered. Formula 1 and other dry-weather racing tyres, for instance, have no pattern at all, in order to allow maximum contact between road and tyre and generate maximum possible grip. Since they are designed for dry conditions, there is no need to provide for wet road grip enhancement and that's why, when it rains during a race, bikes and cars alike have to undergo a change of tyres. Street tyres have to be more versatile and that's why they have lugs (the raised portions), voids (the parts between the lugs), sipes (thin channels) and grooves (thicker channels) that make up the tread pattern.

The tread pattern isn't abstract art. Each part of the pattern has a role to play. Lugs touch the road and high-performance road tyres will have lots of lugs (high contact area) while off-road tyres will have taller lugs (to offer a chance for the tyre to dig into a low-traction surface and hook up to create traction). The grooves and sipes are designed to funnel water away between parts of the tread in contact with the road (also known as the contact patches) and the road itself. This is why the design of the tread patterns is a very involved and detailed process.

Then comes the question of the tread compound. This is a bit of a black art, literally. Tyre manufacturers use a number of chemicals to tailor the nature of the synthetic and natural rubber to the purpose of the tyre. Winter tyres, for instance, could be designed to heat up to deliver optimum performance faster, or engineered to run at lower temperatures. Performance tyres will heat up to deliver optimum performance much quicker and can be expected to perform best at a higher operating temperature. The compounds also determine the life of the tyre. A motorcycle touring tyre, for instance, is designed to be durable and offer grip whereas a sports motorcycle tyre is made for great grip, even at the cost of a shorter life.

Connecting the tread to the inner part of the tyre is the sidewall. This is a structural 'wall' and its height and stiffness determine the feel of the tyre. The innermost part is the bead, which is a rubber coated ring of high-strength fibres (usually steel) that are designed to sit on the rim and grip tightly to prevent any loss of air (especially in tubeless tyres) and prevent the wheel from rotating on the rim. The bead holds the tyre to the wheel under cornering, braking and acceleration forces and maintains its grip when the tyre's structure distorts under these conditions.

Look out for the next installment of Simple Tech where we elaborate further on tyre construction and explain what those numbers inscribed on the side of the tyres mean.