Day Two at the Harley-Davidson University

After what was quite an interesting and insightful day at the Harley-Davidson University, we began Day Two with a few inhibitions. We had to put together the Harley-Davidson Milwaukee 8 engine that we'd disassembled on Day One, and we knew it won't be easy. We were also a bit worried about putting the engine together, only to discover that we'd left a few bolts behind!

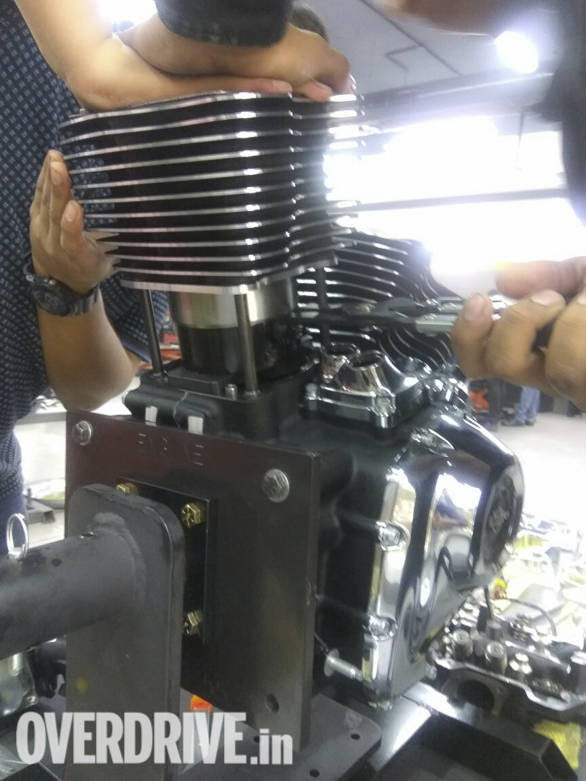

Yeah! That's a lot of engine parts

Yeah! That's a lot of engine parts

John McEaneny, the Harley-Davidson service chief for Asia, was by our side, demonstrating the steps to put the engine back together. I have to say, it's quite a sight to see the various engine parts on the table.

Wd began by applying a thick, industrial strength glue on the edges of the two halves of the crankcase. Since we were working on demonstration engines, we were told to smear the paste as the engine will be put together and taken apart a number of times. In reality, the glue is left to cure for 24 hours before the next step.

After fusing the crankcase together, we began bolting them tight. The process of putting the engine together, in essence, is the reverse of taking it apart.

The thing we had to keep in mind was to ensure we torque the bolts to the specified limit. We did that with the help of a torque wrench.

Step after step we put the parts back in. The oil pump, timing chain, tensioner were put into their respective slots. After that, we put the crank case cover on to finish assembling the bottom half of the V-Twin engine.

Putting the flywheel, coubterbalancer, connecting rods and pistons back in was a a delicate task as we didn't want to damage these critical components. Putting the piston ring back in was quite difficult and it required some strength to lock it in place. Also, we had to align the top and bottom compression rings and a expander ring on the piston and it was turning out or be a test of finesse and patience.

We then fit the lifters, slid the push rods in and placed the rocker arms on top of the valves on the cylinder. Here's where we had to be careful and ensure we didn't damage the valves. While fitting the rocker arm bolts, we made a mistake. We tightened the wrong end of the bar attaches the rocker arm to the cylinder head. On both cylinders. Our fears had come true.

Thankfully, it wasn't a critical mistake and all we had to do was loosen the bolts, albeit with a lot of patience. That's because we had to wait for the hydraulic pressure on the valves to release, while attaching the push rods to the rocker arms.

After about half an hour, we could finally tighten the rocker arm bolts, attach the head covers, intake manifold, knock sensors and oil filter.

The Milwaukee 8 was fully assembled and we couldn't believe we had done it. We did have a bit of a moment with the rocker arms, but otherwise, we built the engine flawlessly and as per the manual. John McEaneny's approval was the proverbial icing on the cake.

Over the course of two days, we had learnt a lot. To take apart a 1750cc, V-Twin engine and put it back together is the stuff most automobile engineering students dream of. We were lucky to have got the opportunity. We've also developed a lot of respect for scores of mechanics who service motorcycles everyday. Working on rebuilding an engine over two days had drained us, and come to think of it, it was just a demo engine. We had room for error; the mechanics don't. Do your trusty mechanic a favour the next time you go to his / her garage. Don't ask him /her to hurry up. Working on a motorcycle takes time, dedication and a calm head. Give the mechanic that room and your bike will be fit as ever.