Simple Tech: Braking explained

Got a fast car or motorcycle? Try driving or riding fast assuming the brakes don't work. You'll find it impossible. As much as brakes are there to control speed and stop the vehicle, their effectiveness is required to ensure you can actually use all that performance in the first place.

The one common phenomenon that connects steering, acceleration and braking is friction. The braking system essentially causes deceleration by converting kinetic energy into heat using friction. It usually has three parts. The first is the actuator which is the human interface - usually in the form of a lever or a pedal. Then comes the force multiplier. This is important because the amount of force needed to stop even a lightweight car - maybe 800kg - is immense. Even the fittest, strongest person will find it hard to press a lever hard enough to produce reasonably good deceleration. The force multiplier takes the form of mechanical, hydraulic or pneumatic systems.

The oldest vehicles used to use mechanical force multipliers or brake assistance systems. They used a set of interconnected levers (playing with fulcrums the same way a crowbar does) to generate brake force. Motorcycles use a much simpler mechanical system that you can see in the drum brake setup. If you look close, you'll see a metal shaft that connects the brake wire to the drum brake. The length of the shaft multiplies the force generated by your squeezing the brake lever.

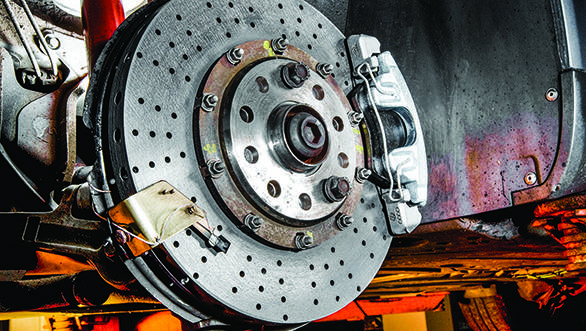

Hydraulic systems replaced mechanical systems because they proved far more efficient and eventually far more reliable and maintenance-free. In the same way that hydraulic power steering works, hydraulic braking systems also use two interconnected cylinders with incompressible hydraulic fluid to multiply a small movement at the actuation end (you press the lever or pedal) into a much larger force but a much smaller movement. The principle is called hydraulic force multiplication and you can see it working in everything from a hydraulic jack to almost every single disc brake in cars or bikes.

Pneumatic systems are much less common in cars and bikes. The vacuum based system connects the pedal and brake, via a linkage, to both ends of a vacuum tube. Pressing the pedal moves a diaphragm into the vacuum and causes the brakes to be actuated. This is common on trains today. Heavy vehicles use an alternative that uses compressed air. In function and layout, it is similar to hydraulic systems but uses the pressure of the compressed air to generate brake force. These systems have many more components - like a storage tank for compressed air, air cooling, filtration and pump systems etc. But the advantage is that these systems can work even if there are leakages and that gives them an in-built fail safe. Because they do not use hydraulic fluid, these systems are also convenient to service and maintain and the air which these systems use is freely and readily available.

So you press the pedal and the force multiplier mechanism applies a strong force, then what happens? As we said, in every case, the brake uses friction as a process to convert kinetic energy into waste heat. The loss of energy causes a drop in speed, leading to what we usually call braking.