Simple tech: Seals and gaskets II

Last month we discussed in detail the importance of seals and gaskets. This time, let's look at where they go vehicle and what they do there. On any machine, seals and gaskets are all over the place. But they're not only in the machinery. They also go on, for example, door sills - rubber gaskets that isolate the cabin. Should we be surprised? That's exactly what they do on machines too! They isolate stuff and prevent the mixing of stuff that shouldn't mix.

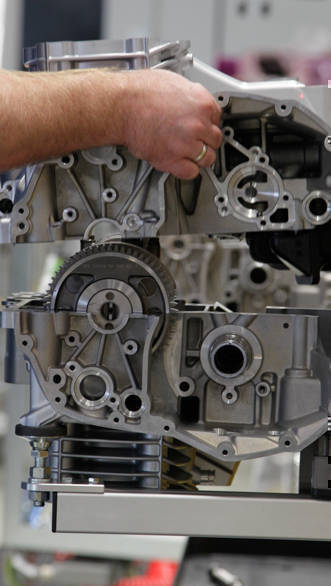

There are three kinds of sealing systems. Gaskets and O-rings are used to separate things when two stationary parts are involved. This could be two halves of casings, covers or drain plugs. They are deployed to prevent internal fluids from spilling out and to prevent external impurities from getting in.

Seals, the third category, are used when one stationary part has to work with a rotating or sliding unit. Examples include shafts that exit the engine, gearbox, differential, or on motorcycles, telescopic forks and dampers. The tolerances today, and the need for the movement requires lubrication and cooling. The seals prevent fluids from being lost, or spilled.

Let's start with gaskets. The cylinder head gasket sits between the cylinder head and the engine block. It has the most arduous task - to prevent four fluids from mixing with each other. There're lubricants for camshafts, coolant for thermal stability, combustion gases and of course, fuel. All four are vital but their mixing can be catastrophic. The gasket also has to bear the temperature and stress from combustion. So they have to be extremely strong too. Popular gaskets including multi-layer steel, copper, ceramic, graphite, and earlier asbestos. All have extreme high temperature and pressure resistance but for graphite seals.

For places that are not so extreme, like between gearbox casings, gaskets can be made from industrial paper and teflon (polytetrafluoroethylene) - both are common. Copper and aluminium are used where the casing's surface finish is of a very high quality - so durability is high, but sealing properties are not so good. Some manufacturers now also use liquid sealants, like silicone which dries up to provide some of the best sealing money can buy today. But silicone seals get destroyed during dissasembly and must be applied afresh each time.

Gaskets for engine sump drain plugs are usually made of copper or aluminium for their high durability. These, popularly called washers, also prevent wear and tear on the plug itself as well as the sump hole. The gaskets are softer and absorb the pressure of tightening. O-rings are round rings made of rubber, usually elastomers or nitrile rubber. The most common form is in your pressure cooker. Automotive O-rings are reliable, durable and have a round cross section. They sit in grooves made for them in the mating surfaces. They provide a point of contact between mating surfaces and squish slightly under pressure once tightening. This means perfect sealing under high pressure conditions such as joints in hydraulic piping (brakes and steering), high pressure fuel pipes and injectors, cooling water lines and vaccum lines. O-rings also find use in hydraulic cylinders like the brake master cylinder and in hydraulic dampers and telescopic forks.

The final class is seals, or mechanical seals. These are used in rotating machinery - like between a rotating shaft and casing. A common example is the gearbox drive shaft. These seals come in a two-part ring design. The stationary ring is placed inside a groove on the casing, usually with a high quality surface material like teflon. A rotating ring is places on the shaft, usually made of high quality carbon. The rings are pressed together by a high tension spring. Once your start the machinery, the carbon ring rotates with the shaft and rubs against the silicon ring. Teflon reduces friction while the pressure ensures a perfect seal.

In hydraulic cylinders like dampers or telescopic forks, a special type of seal called the lip seal is used, usually made of nitrile rubber. It is mounted on the part of the piston which stays inside the cylinder and rubs with a constant but light pressure against the sliding motion of the piston and prevents oil from leaking out. This is why it is important to keep the piston's external surface clean. On a telescopic fork, dust can damage the lip seal and the hydraulic fluid can leak. This is why telescopic forks have a dust cap (which you can see) that protects the hidden lip seal inside.

Lip seals have a constant rubbing action, so they wear out after a given number of running hours and need to be replaced. Gaskets and O-rings also deteriorate over time, via oxidation as well as reactions with operational fluids and they have replacement intervals too. The universe of gaskets and seals is vast but these are the primary three types that you will encounter on our cars and bikes. Their job is vital and you must take care of them for fault-free running.