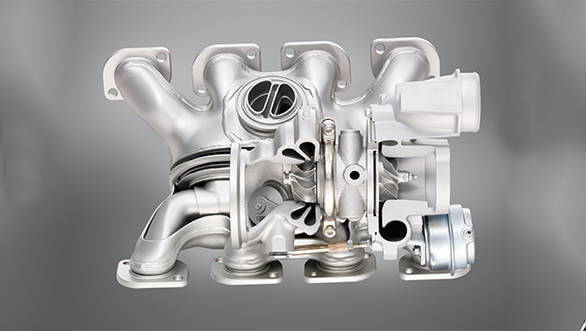

Simple Tech: The exhaust manifold

If you read the last Simple Tech, you know we got a glimpse into how the inlet manifold impacts and enhances engine performance.

The exhaust side, or exhaust manifold, uses similar logic for tweaks that increase performance too. In fact, even in construction it is very similar to the inlet. The exhaust manifold is usually a metallic tube, usually cast iron, steel or ceramics. This tube if connected to the cylinder via a runner, a small diameter pipe. And all this is set up to collect spent exhaust gases and helping them make a smooth exit, via the turbocharger if the engine has one, or directly to the exhaust outlet.

The manifold is also designed for other functions. One is to prevent exhaust gases from being sucked back into the combustion chamber and inlet manifold during the short slice of time when both valves are open (aka valve overlap). The exhaust manifold also carries off some of the heat that might cause thermal stress inside the engine otherwise.

But the primary design challenge for the exhaust manifold revolves around the two issues that engineers are working on ever since its inception. Over a century of work!

First, exhaust gases move fast. And they can, in theory, 'drag' fresh intake charge with them into the exhaust during valve overlap. This is a waste of fuel and it can prevent proper combustion too. The lack of an exhaust manifold or a badly designed free flow exhaust can easily cause this. What you get is a loss of fuel economy as well as power.

On the other hand, if the exhaust gases cannot exit the combustion chamber smoothly, they build up a pressure that the intake charge must fight against. This reduces the flow of fresh charge as well as mixes exhaust and fresh charge together. This means a reduction in both power and torque. The effect is felt the most at peak revs. A chocked manifold - with carbon deposits, or a bad design will lead to this.

In essence, an engine needs to breath both in and out properly to perform. Engineers have to find the balance between the two. Let's look closer.

During the exhaust stroke of the engine, the exhaust valve opens and the piston moves up to push the exhaust gases out of the combustion chamber. Obviously, this consumes some of the energy we generated in the power stroke - a bit of a waste.

Enter Helmholtz resonance. That is the idea that high velocity air has inertia, we talked about this when we discussed inlet manifolds. The exhaust gases exit the cylinder as high velocity. When they pass through the runner into the larger exhaust manifold, they expand and slow down drastically which creates a high pressure 'lump' of air thanks to its inertia. This lump, travelling towards the exit is bounced backed towards the runner by gases already ahead at a relatively higher pressure. This ends up pressurising the runner - we call this backpressure.

When the exhaust valve opens again on the next cycle, backpressure will prevent the exhaust gases from flowing freely towards the exit. This resistance causes the gases to oscillate inside the runner hapenring the flow of gases out, and consequently, affecting the incoming charge as well.

The engine now has to do work harder to maintain its state of work. Performance falls and the higher the revs (gases need to move faster) the greater the impact is.

But if you can design the runners so that the pressure pulse is moving away from the cylinder at the right time, it would create a vacuum and speed the exhaust gas along. Efficiency and performance both will increase! It's like turbocharging but free.

Now, there are limits to this process. The rate at which gases leave the combustion chamber should not be more than the rate at which the air-fuel mixture is entering. This prevents fuel wastege. So the design of the length and diameter of the runners is created to suit a particular engine speed range.

High performance engines, due to their narrow work goals, can use specially designed exhaust manifolds that work very well in the desired powerband. Free flow exhausts on these kinds of engines also work towards that very goal.

But for normal cars, the variable inlet tract/manifold serves to widen the range of positive impact. It consists of long runners that snake around for tuning their length with bypass valves that add or subtract length. So the engine can enjoy the benefits of a long runner at low revs but still depend on a short runner at higher revs by closing and opening appropriate valves. The process is electronically controlled.

Turbochargers, ever more common, increase the relevance of the exhaust manifold by using the high velocity of the exhaust gases to spool up the turbocharger's vanes. Better manifold design executes the process faster, wasting as little time and energy as possible, reducing turbo lag and increasing both efficiency and power. And that, you already know!