In conversation with Olaf Hedden, president, Pierburg GmbH, KSPG Automotive

KSPG AG is the parent company of Rheinmetall's automotive sector and a global first-tier supplier to the automotive industry. Low emissions, reduced fuel consumption, upgraded performance, reliability, quality, and safety - these are the focus areas that drive innovation at KSPG. The group comprises three divisions namely Hardparts, Mechatronics and Motorservice and employs a workforce of around 12,000 employees at its production locations in Europe, North and South America, Japan, India and China. We got an opportunity to interact with Olaf Hedden, president of Pierburg GmbH, KSPG Automotive where we talked to him about the BS VI norms, KSPG's plan for India and more.

With the new Bharat Stage VI emissions norms to be introduced by 2020, what technologies do you intend to bring into the Indian market?

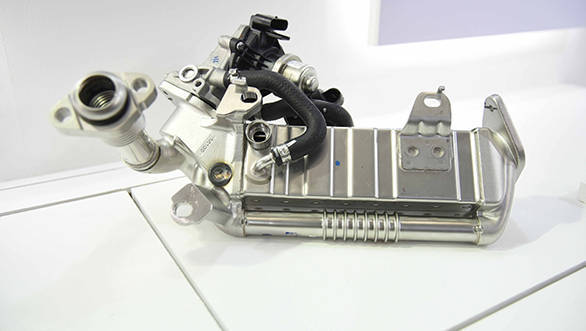

We are one of the leading European companies for emission control systems. In Europe, Euro VI is already established and we have a lot of products for Euro VI applications. Now with India deciding to upgrade to Bharat Stage VI which is equivalent to Euro VI emission norms, we can introduce a lot of our products to India especially the high pressure and low pressure exhaust gas recirculation systems and modules along with exhaust gas coolers and valves. We see big potential for us primarily on the commercial business side. India, as a market, demands cost effective solutions which is ideal for us as all our products and solutions are very cost effective. Even for the passenger car market.

But it is going to be a challenge to meet the price targets of Indian companies because diesel is going to be more expensive in the future. This is something that we need to work out with our partners in India. I don't think we can bring all our one-to-one solutions from Europe into India. We need to think and find suitable solutions for India.

The commercial diesel market is growing in India and we do see a growth potential there. We have products available in Europe for light, medium and heavy commercial vehicles. Most likely our heavy duty solutions for Europe won't be applicable in India. But we can offer our wide range of solutions for light and medium commercial vehicles to our Indian customers. The benefit of our application when compared to a Selective Catalytic Reduction (SCR) system is that ours is much smaller and a lot more effective. While our application can work in sync with SCR, in India, the SCR system can be removed completely and only our application can be used. But this too needs to be worked upon and fine tuned.

The Indian Government has introduced the Make in India initiative to encourage companies to manufacture in India. Among the technologies that you intend to bring down from Europe, what are the localisation levels being targeted?

We are always trying to localise manufacturing in India as much as possible. We already have a plant in Takwe, Pune where we are manufacturing mechatronics components, especially for emissions reduction. We want to bring as much business as possible to our plant and once it pays off and a certain quality level is reached, we are going to localise further. The next challenge in this regard is to find the right suppliers in India who can fulfill our demands for quality and technology. Our goal is to add as much value as possible to our operations in India.

Currently what are the growth prospects for KSPG in India across the different verticals it is present in?

India is a huge market and the ratio of the number of cars to the number of people is still very low. So, we can already see that in the future, the Indian car market is going to grow. Currently, India is the highest growing car market globally but at a limited level. If the infrastructure improves, there will be more potential for growth. This will allow us to bring our entire product portfolio to our Indian customers. Our products and solutions are not just limited to emissions control. We also have products to reduce fuel consumption. For the Indian market, the cars need to be cheap to buy and run, which means our solutions for reducing fuel consumption have a lot of potential here. We already supply products for friction reduction which improves fuel efficiency and we see more demand for these in the future. Our variable water circulation and coolant pumps reduce fuel consumption by around two to three per cent and we foresee a higher growth for them as well. So India is an important market for us and we hope that it grows faster than it did in the past.

In India, especially in the automotive sector, it's a challenge for companies to find and retain skilled labour especially in the field of engineering. What is KSPG's take on it?

Yes, this is true and we are facing the same problem. It's not only in engineering but it's the same in manufacturing as well. We are an engineering driven company and we need to have local engineers as resources. Currently, we have a good team with a strong skill set that is vital to us. We try our best to keep them happy. We do that by ensuring they undergo a lot of training to improve their skills and help them get acquainted with emerging technologies. This helps them get better and also stay in the company. Of course, we also ensure adequate wages get paid. But that is not the only thing that keeps people happy over a long term. We also let our people work with the global teams and let them gain experience in different markets. So it also gives them a personal satisfaction and makes them competitive at a global level.

In the transportation and mobility sector, electric and hybrid vehicles are currently trending. Are you working on any solutions for the same?

Yes, we see this trend too. With respect to electro mobility, we feel that hybrid vehicles will have a larger role to play especially in Europe and the United States. In India, we think this will eventually trickle down but at a much later stage. We are developing products related to electro mobility but it's not something that we can talk about right now. We have developed our own two cylinder engine as a range extender for electric vehicles. With this, we can extend the range from 100km to around 400km. This showcases our innovation and more technologies can be further derived from it. So, we are already preparing ourselves for the future.